Interview: The new B4I Innovation Centre will help companies with digital transformation

Many plans for linking science and industry have emerged in the Czech Republic in recent years. Some have taken early

but others have been implemented over time. One of the successful projects is B4I (Brain4Industry)

and its newly opened innovation centre located in Dolní Břežany.

“The aim of the project, which involves a consortium of institutes of the CAS, state institutions and industrial partners, is to support companies in their technological transformation within Industry 4.0,” says Andrej Chrzanowski, director of B4I, in an interview with Technicky týdeník.

The construction of the B4I centre took less than two years, but when the idea of such an institute was born?

It was about 10 years ago, when I was working as a technical director at the Czech Armaments Factory. At that time, I was thinking about how we could continue to develop our research and development areas, and I thought that we should take the path of an independent workplace dedicated to applied research in emerging technological areas. So I put together the basic premises of this concept, a business plan and started looking for partners with whom it would make sense to collaborate on such a centre.

In 2014, I met with the then director of the Institute of Physics of the CAS, Jan Řídký, and I found out that this institute has been cooperating with industry at a certain level since the 1990s.

In fact, one could say that he was a pioneer in linking science and industry in the Czech Republic. At that time, the FZU already had a huge potential in people and technology, and it had heard about the possibility of an independent workplace for applied research, so we started to cooperate on the preparations.

In the meantime, we began to negotiate with other companies, scientific and state institutions, and also with Věšek Michalik, who was then the mayor of Dolní Břežany. He was also enthusiastic about the idea of building another science centre. I would say that 2016 was the turning point for the creation of the B4I centre.

What happened that year?

At that time, we founded the company CARDAM (Center of applied research and development for additive manufacturing), with three entities becoming the owners: two industrial companies – Česka zbrojovka and the company Beneš and Lát – and FZÚ AVČR, for which Alexandr Dejneka from its Optics Section became the key man for our further cooperation.

The Institute of Physics had the background of the CAS and strong competences in research, development and development of materials, coatings, as well as equipment design. Even then we knew that if we really wanted to help Czech industry, the centre needed to focus on additive technologies and digitalisation.

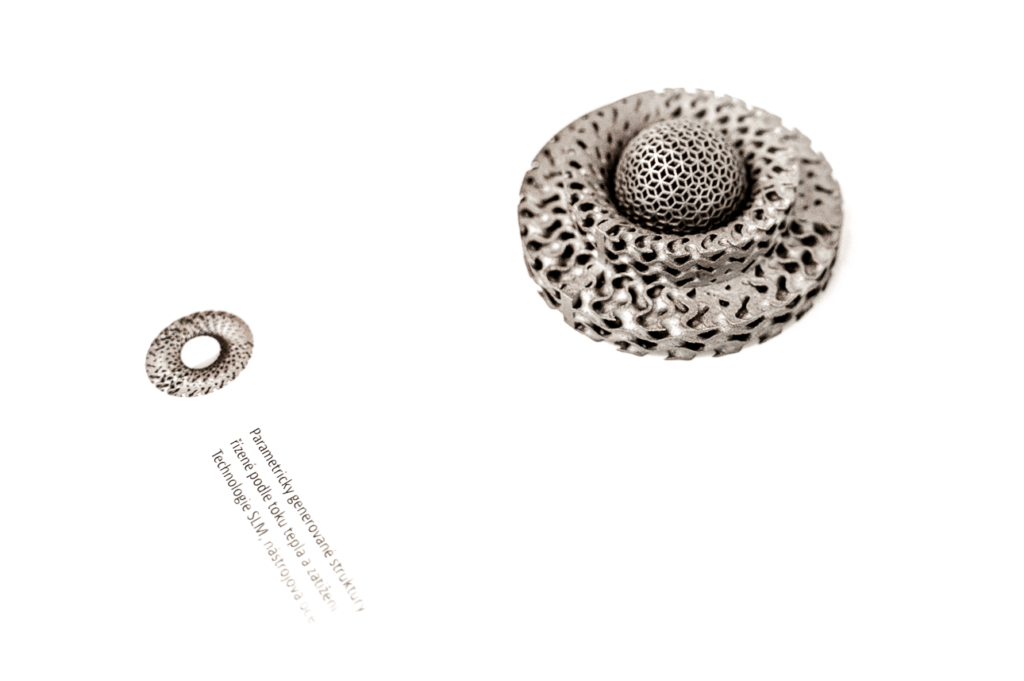

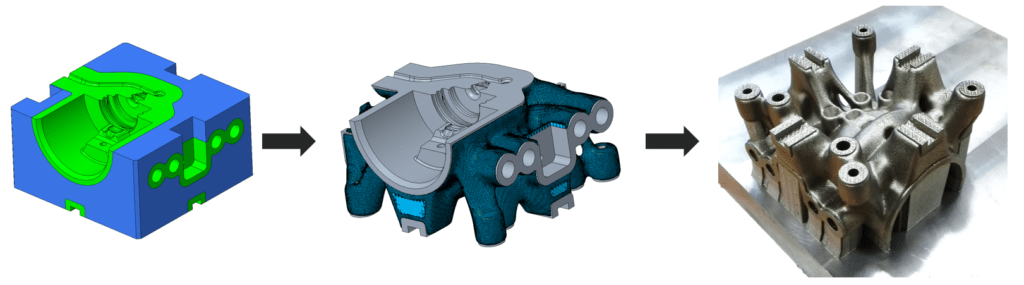

Thus, a team of people began to emerge, focusing on core competencies in emerging technology areas and on the complex process of product research and development from design, mathematical calculations, topological optimization to actual production and post-processing.

In the coming years, we have successfully obtained a grant program from the Czech Technology Agency and we have expanded our team with additional experts. New projects implemented within the NCK MATCA (National Centre of Competence for Materials, Advanced Technologies, Coatings and their Applications) focused on the development in the areas of research and development of materials, sensors and coating technologies.

In 2019, we have already started working on the B4I business plan, as a consortium consisting of the Institute of Physics of the CAS, the Institute of Thermomechanics of the CAS, the Central Bohemian Innovation Centre, the science and technology cluster STAR (Science and Technology Advanced Region – bringing together research centres, private companies and municipalities in the region south-east of Prague – ed. note] and the aforementioned CARDAM company.

Another important milestone was the acquisition of a European subsidy programme for the development of digitisation and from 2022 we are part of a network of European digitisation hubs, with B4I being one of the key hubs for digitisation, additive technologies and the application of artificial intelligence.

Why did you decide to focus on additive technologies and digitalisation?

There are still few companies in the Czech Republic that have a final product, and if they do, they are mostly foreign companies. Our economy consists mainly of small and medium-sized companies, which mostly act as suppliers or suppliers of suppliers of larger multinational units. From an economic point of view, SMEs thus have very limited opportunities for their business and product development, as they ultimately operate with a small margin. Logically, they cannot afford to invest the same amount of money from their economic result in the development of their own people, modern technologies, product development and innovation, and in their future as their foreign competitors.

We are also talking about the fact that Czech industry is in a period when it will have to undergo a certain transformation and it will be absolutely crucial that it gradually gets to products with higher added value. It is important for Czech companies to be able to move up the food chain towards higher profitability and for suppliers to become entities that can control their margins. This is actually our goal. We want to help Czech SMEs change their business models so that they can bring new products and use the latest technologies.

How can the centre in Břežany help these companies in this shift?

Imagine a company that does not have its own R&D (research and development). For example, it is a manufacturing company that focuses on its own production and the necessarily related technological preparation, and such a company would like to move towards a final product, service or a completely new business model. In doing so, it naturally faces considerable barriers to entry due to the lack of experienced and competent people and the high financial requirements for investment in new technologies and the like.

In this case, if they turn to us, they will get the necessary comprehensive expertise, services and knowledge in the area of research and product development that will enable them to implement the product on very favourable financial terms.

B4I is an applied R&D facility, so we can offer this potential to companies. We are backed by facilities, technology and a team of people with deep expertise and know-how. Companies can start working with us to create new products or optimize existing products using modern technologies. At the same time, they can test development and production processes with us on our technologies as well as on technologies available to us within the framework of partnership relations, as we cooperate with Czech universities and selected technology partners.

Companies can test new processes with you, but they should produce at their own facilities. Will the centre also sell 3D printers?

We don’t primarily sell technology, we are a team that is primarily there to help companies develop the product, debug and transfer the manufacturing process and innovative technology into the business. We are able to assist and oversee the integration of the technology as we have all the competencies to do so. Whether companies decide to purchase identical production equipment as we have here at the center or different ones, we can assist them in the deployment of technology. The only difference is that when a company chooses technology from another manufacturer, the integration takes a little longer. Therefore, in principle, the ideal solution is to buy technology from the manufacturers whose technology we have here, but sized to the expected production capacity to make production both more productive and more efficient.

So the centre will also function as a counselling centre?

That’s exactly one of the paths we took. Companies can try out and adopt new technologies with us. But we are also ready to provide them with comprehensive financial services including investment return models and financing options. We are able to collaborate on business plans for new products, integration plans for digitalization, etc. We provide companies with all our know-how.

It doesn’t make sense for the centre to operate just as a showroom, we want to provide a whole package of services, which means we have to get to know the company very well, we have to understand the customer’s needs, what kind of product they are making, what strategy they should choose so that they can move on to new products with higher added value while effectively using digitalisation technologies. This is one of the huge potentials, by the way, the correct use of digitisation.

However, everyone in the Czech Republic interprets digitalisation in their own way. How do you perceive it?

I think that most companies are currently addressing issues such as process data integration or the wider development of automation and robotics within their production systems. So companies have some experience with digitalisation, but they are not holistic. We also encounter companies that have acquired some enterprise system as part of digitalization, but without a deeper understanding and without considering the future interdependency on data integration with suppliers and customers.

We are therefore taking a comprehensive approach to the potential of digitalisation. We look at all possibilities from the start. We approach their development within the company as a strategic concept that encompasses all levels: technological, financial, organisational and communication. To put it in perspective, this is the so-called strategic roadmap. So, we work with our customer on a structured and strategic development concept in the entire depth of digitalisation technologies and then draw up a roadmap with time and financial requirements.

We recommend that the implementation strategy should also include a communication and organisational strategy, as it is closely related to the overall transformation of the company. The strategic concept is preceded by an in-depth analysis of the company, which we provide free of charge, as B4I is part of the network of European digitalization hubs and can provide this service under discounted conditions.

What can you offer companies as part of digitalisation?

In addition to a conceptual approach to digitalization strategy, our department specializes in the area of product development and realization, or the entire product life cycle, using a broad portfolio of additive manufacturing technologies, coating technologies, laser surface treatment technologies, heat treatment and other finishing technologies.

We develop and implement physical products whose production process is physically debugged, tested and validated in our technological facilities. We are also able to simulate this physical product design and manufacturing process, creating a digital twin of development and production. We are talking about a digitization thread through which not only the actual product design takes place, but also the simulation and implementation of the entire production process. The product thus becomes the data containing all the information about the product.

We use proprietary neural network-based algorithms to develop appropriate product structure and mechanical properties, and we are able to collect data from manufacturing technologies and optimize production processes. As part of product development, we provide standard mathematical calculations, structural analysis, thermal analysis, as well as specific calculations, fast impact processes and multiphysics tasks.

Linking machines and simulation models then allows data models to be improved and optimized, which is related to optimizing production costs, speeding up development, etc. We must realize that the use of AI applications will gradually affect development and production processes, the entire product life cycle, to a greater extent, which is why we are also focusing on this area.

So what technologies can companies encounter at the B4I Innovation Centre?

In the B4I Innovation Centre you will find two industrial laser 3D printers. The printer with SLM (selective laser melting) technology is designed for printing from metal powders, while the SLS (selective laser sintering) technology prints products from polymer materials.

Then FDM (fused filament fabrication) technology, which is one of the most common, but one of the printers we have differs from competitors in its speed and great material versatility. Another is the Delta printing kinematics, which allows printing at high speed with high spatial precision, thus reaching industrial level parameters.

We also have two DLP (digital light processing) printers, the first of which uses light curable polymers for printing, is highly accurate and enables high volume printing. The second uses an LC display for curing and is also very fast.

We also have SLA (stereolithography) printers that use a laser to print from light curable polymer, which again provides the ability to print smaller parts very quickly and accurately.

Of course there are technologies for post-processing of printed parts or their various testing.

Coming back to consulting, companies in the Czech market already offer transformation consulting. What do you think is your added value?

It is mainly our knowledge, experience, and commitment. European industry is changing, facing higher productivity competition from Asia and other regions, and the Czech industry, due to its export dependence on Germany and European countries, will have to find its way to its products and new markets. One way is through investment in education, applied research and development in selected fields, and the ability to learn how to sell the results of science and research.

We were commissioned for this task several years ago, so I dare say we already have some experience in the areas we offer that you won’t find at competing sites. Our uniqueness is also in our connection with the Institute of Thermomechanics of the CAS, which is a leader in the field of materials engineering, and in our connection with the Institute of Thermomechanics of the CAS and the HiLASE center. Thanks to our unique expertise, we can offer companies services unavailable on the Czech market.

Our mission is to genuinely help companies with their digital transformation and provide them with the best solution for their business, offering an independent, expert, and responsible perspective without the need for immediate investment in expensive technology.

How was the construction of B4I financed and how do you plan to finance the operation?

The Ministry of Industry and Trade (MIT) and the FZÚ contributed financially to the construction of the centre in a ratio of approximately 70:30.The funds for the operation and provision of consultancy services in the field of digitalisation are obtained through the Digital Europe programme, where the financial resources are half covered by the EU and half by the MIT.

Primarily, we operate as an applied research and development institute, so we are obliged to finance the dominant part of our projects from grant activities with industrial partners, but in the long term we also focus on the commercialization of technologies and the results of expert activities, which in a sense means that we will also offer outsourcing of technological background to all companies that will use these technologies for the implementation of, for example, prototypes.

Source: This interview was published in Technical Weekly no. 13/2023

Author of this interviews is Kristina Kadlas Blümelová

Download the full interview here (pages 12 and 13).