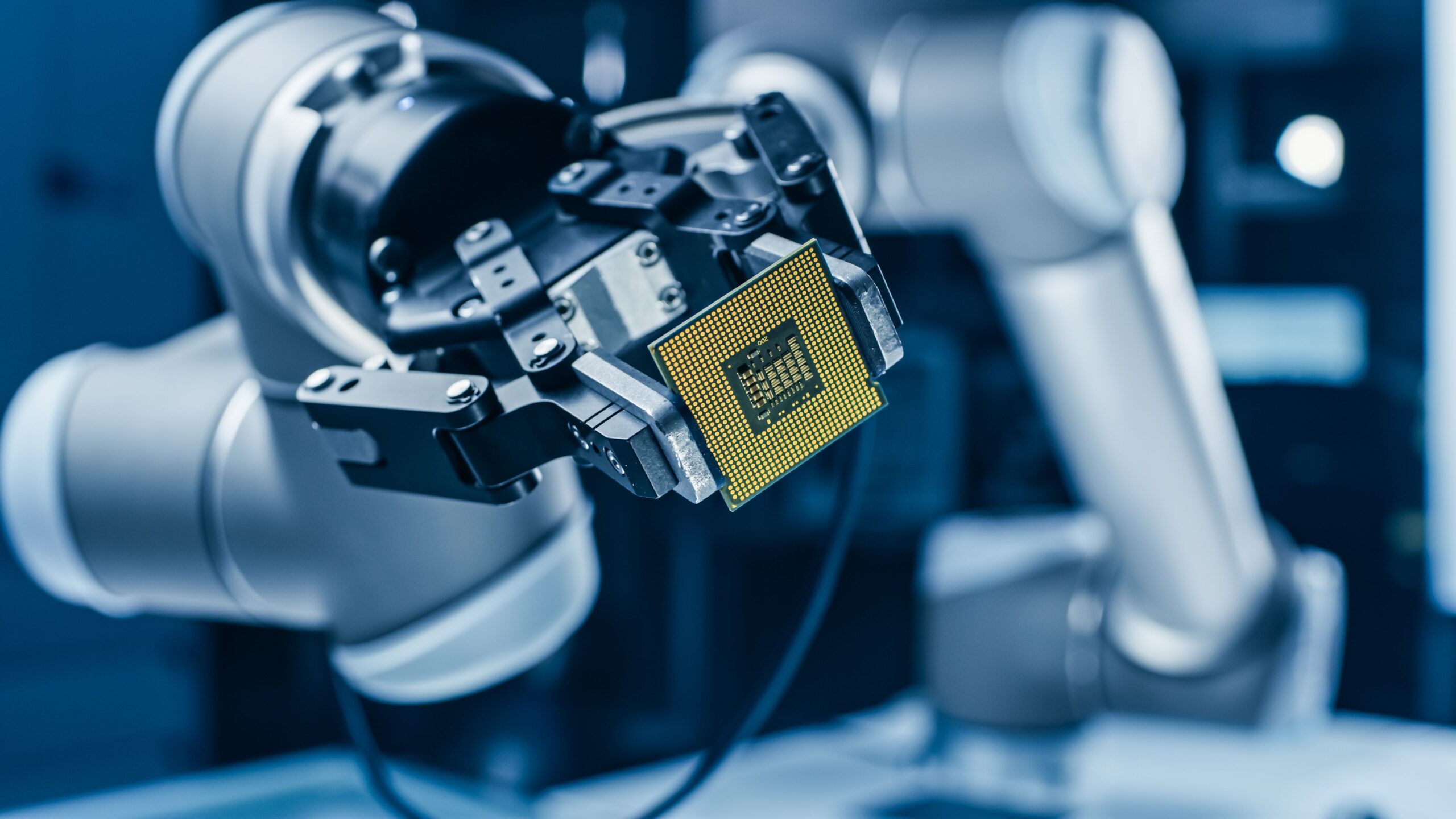

Sensorics and robotics

Automating manufacturing processes with robotics and sensors takes manufacturing processes to a new level of efficiency and innovation. The collaboration of our leading experts in sensors and artificial intelligence has a high impact on production optimization, predictive maintenance, output quality, cost reduction, faster decision-making and flexibility in the face of demand changes.

In-house experts in sensors and artificial intelligence

The benefits of robotics and sensors in the daily work of a manufacturing company

Increased productivity: robots are able to work continuously and accurately, increasing production capacity and reducing cycle times.

Automation reduces the need for human labour and minimises the risk of human error, leading to savings in the long run.

Safety: robots can take over dangerous or strenuous tasks, reducing the risk of workplace accidents for human workers.

Product quality: robots work with high precision and consistency, increasing the quality of the final products.

Flexibility: industrial robots are often programmable, making it easy to adapt their tasks to new production requirements.

Monitoring and predictive maintenance: sensors allow the condition of the equipment to be monitored, allowing predictive maintenance to be carried out, minimising downtime and extending the life of the equipment.

Do you have a question or are you solving a specific problem? Contact us

Milan Chlada

Researcher at the Institute of Thermomechanics

The Institute of Thermomechanics within the Brain4Industry consortium is a top workplace for sensors and artificial intelligence. In cooperation with other consortium partners, we are able to offer a comprehensive solution for a specific production plant.