3D scanning

3D scanning enables the creation of accurate digital models of real objects and spaces, which are then used for analysis, simulation and optimization of production processes. For manufacturing companies, 3D scanning provides many advantages and opens up new possibilities in design, development and production quality.

Custom prototype development

Diverse applications in production:

- Digital copies: One of the main benefits is the ability to quickly and accurately capture existing objects or parts and create their digital copy. This allows manufacturers to easily reverse engineering, which is particularly useful for refurbishments, replacement parts or developing new product variants.

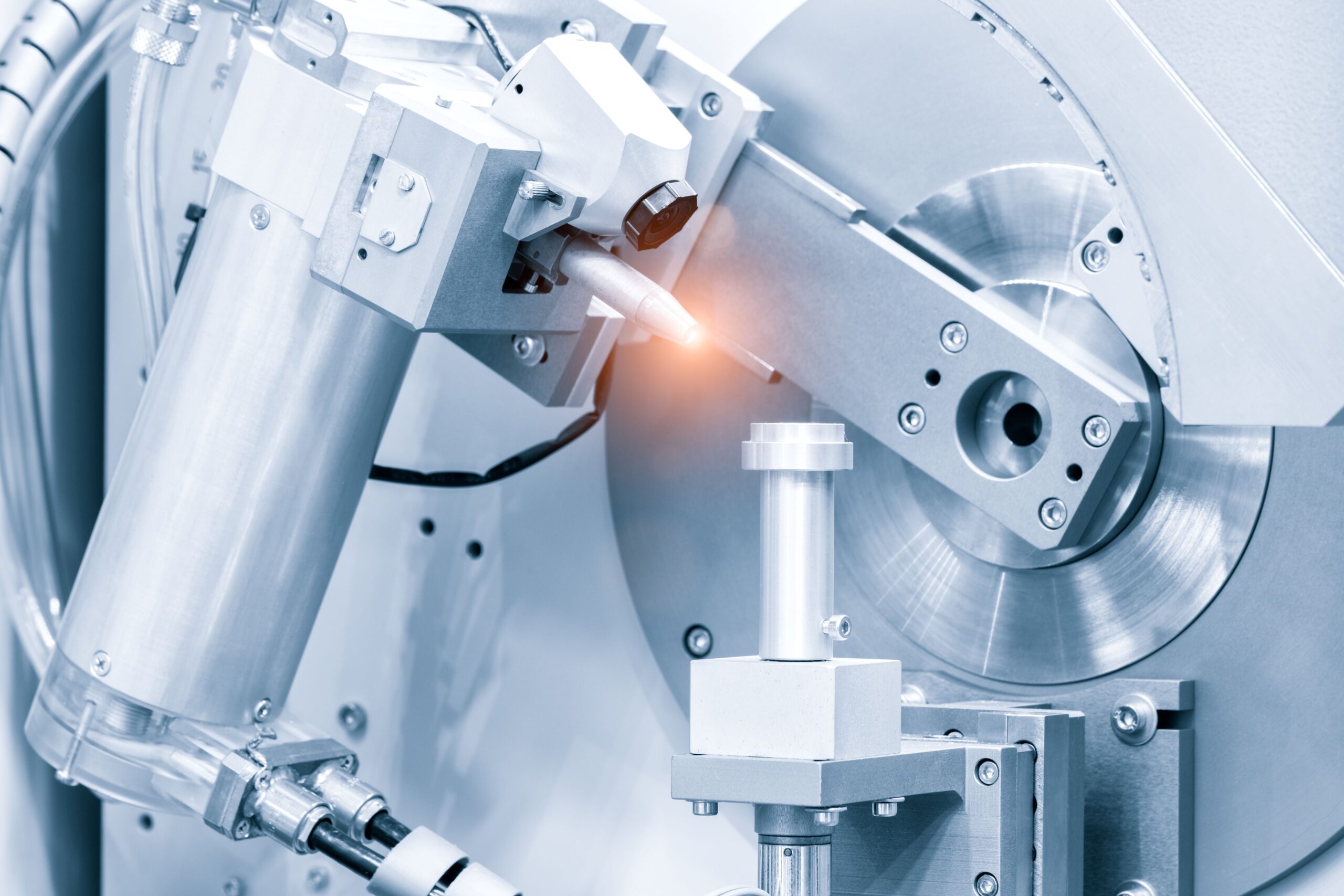

- Prototyping: Using scanning digital models can be created that serve as the basis for 3D printing, CNC machining or other manufacturing processes. In this way, production times are reduced because designs can be quickly converted into physical form.

- Quality control:

By comparing scanned models with reference data, deviations and defects can be easily detected. This minimises the risk of errors and increases production accuracy.