5+1 top trends in additive manufacturing for 2024

The global additive manufacturing market has been growing significantly. The coronavirus pandemic, the impact of conflicts and changes in the energy self-sufficiency of countries have allowed 3D printing to come to the forefront and take full advantage of its benefits over conventional methods. The overall size of the additive technologies market was worth €10 billion in 2022 and the market is projected to grow at a significant rate of around 18% until 2027. It is therefore worth keeping an eye on where this young market is heading and what its prospects are. There are certain trends in this sector too, which were already outlined at last year’s major trade fairs in Asia, the United States and Europe. Which are they? we looked at together with Tomáš Jetmar, Head of AM Systems and General Manager of NCK MATCA

1. Vývoj nových materiálů pro 3D tisk

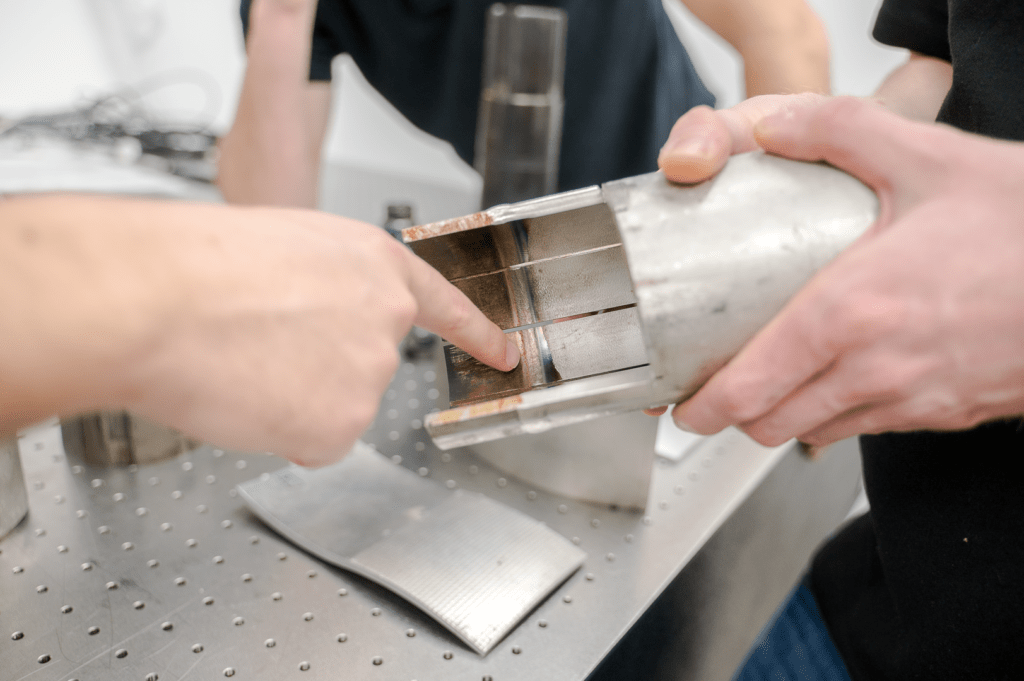

In the additive manufacturing industry, one of the key trends is diversity of materials and their innovation. New blends and composites will offer manufacturers a wider range of options in product development and manufacturing, from super lightweight structures to highly durable materials and finishing options.

“A significant competitive advantage is in-house research and development, which enables a faster and smoother transition from research findings to the development of practically applicable materials,” says Tomáš Jetmar general manager od NCK for MATCA who also who deals with material development and adds: “It also provides greater flexibility in experimenting with new materials, technologies and processes. What also proves important is the control over the entire process from research through development to testing and implementation, ensuring consistent quality and optimization of the resulting materials.”

For companies, investing in in-house research and development is a costly item. “This makes Brain4Industry an ideal choice, especially for small and medium-sized companies. This is because it is one of the few Czech entities with its own state-of-the-art facilities for applied research and development of materials, whose capacities and outputs can be used by companies or directly shared in joint projects,” Tomáš Jetmar invites companies to active cooperation.

2. Larger printable area and integrated production processes

The pressure for speed and efficiency will also be reflected in the design of printers that will enable the production of larger, more compact and complex parts in a shorter timeframe, for example for the automotive industry.

At the same time, additive technologies will be more integrated into the overall production process, again reducing production time from design through production to the final product. “This will completely change and speed up the overall process from idea to final product,” Tomáš Jetmar confirms from his experience, but adds: “What, however, represents the absolute basis for these benefits and applications are the right choice of systems, mutual compatibility and integration. At this stage, Brain4Industry offers consulting services (professional technological and financial) and project supervision to ensure that the chosen solution meets the requirements and individual needs of the company from selection through installation and launch.”

3. Customization -– small series and personalized products

3D printing enables creation of unique and personalised products, and this unique capability will increasingly be on the radar of manufacturers and customers alike. “The advent of production lines that are fully customisable to customer needs will be one of the major trends of 2024,” says Tomáš Jetmar. “Not only can they efficiently produce small batches of products, but they will help to personalise products to increase their utility or aesthetic value.” This will open the door for new business models and strengthen the competitiveness of companies in the market.

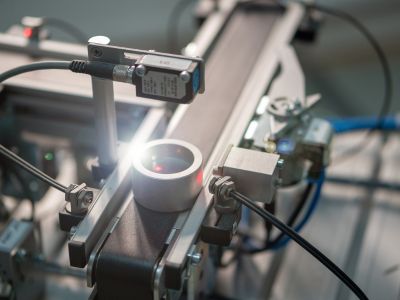

“At Brain4Industry, we provide companies with these personalisation possibilities through our own research and development of materials as well as through post-processing technologies, laser methods or plasma technologies,” adds the exceptional technological background of the consortium’s main guarantor. The applications are truly wide-ranging, from luxury cars in small series, to individually manufactured medical devices, to the hygiene requirements of the food industry, more durable electronics or the impressive design of consumer goods.

“Companies can use our so-called Test Bed service to test a specific technology or solution in a real process, evaluate the results and invest in similar equipment based on the results,” encourages Jetmar companies to use the capacities of the innovation centre.

4. Sustainability as the first side effect of additive manufacturing

With the increasing emphasis on environmental protection, the additive manufacturing industry will focus on more environmentally friendly production processes, less waste, and optimised warehouse management or the development of eco-friendly materials. Its key role will be to avoid unnecessary consumption and waste at all stages and levels of the production cycle and to promote better quality and longer-lasting products as much as possible.

“Although sustainability and carbon reduction are often not the primary motivation for digital business transformation or the use of additive technologies, they tend to be a very pleasant side effect. That’s why at Brain4Industry we look at manufacturing as a complex process and try to show companies that there is a solution that will ultimately deliver far more positive results than what they initially required,” confirms one of the strongest trends, Tomas Jetmar.

“In addition, with in-house experts, we can calculate all costs and carbon footprints in advance to show companies the impact of different options and the pursuit of decarbonisation. We can provide specific help with the right ESG(Environmental, Social and Corporate Governance) policy.”

5. Guided artificial intelligence and smarter factories

With the increasing complexity of additive processes, artificial intelligence will play an important role in optimizing manufacturing operations. Algorithms can react quickly to changes in the production process, market or customer behaviour, but they are also increasingly gaining ground in production planning and trend forecasting.

“At Brain4Industry, we have strong expertise in machine learning, which is the development of algorithms and models that can automatically improve performance based on experience or data. It achieves great results especially in the predictive maintenance of production machines and entire factories, but can be applied in many other fields.”

AI is expected to be the most implemented tool in the next two years. At the same time, up to 70% return on investment is expected in supply chain management, quality control and purchasing.

The increasing involvement and use of data logically brings with it issues related to the proper handling, use, storage and protection against theft or even misuse of data. Cyber threats are thus another strong theme for 2024, which we are also addressing within Brain4Industry.

EDUCATION – the biggest trend of modern times

Education is generally considered to be the biggest trend in modern life. The internet, the pandemic and advances in technology have opened up previously unseen opportunities for anyone who wants to develop themselves, in absolutely any field and any skill. Keeping up with rapid developments is also the only way for individuals and companies alike to maintain or gain a competitive edge.

With the advent of additive technologies, especially in industry, there is a need for specific education to meet the new challenges At Brain4Industry, we also consider education to be the strongest driver of the successful transformation and boost of Czech industry.

“That is why we have established the B4I Academy to provide comprehensive education in the field of digitization and in 3D printing, materials engineering and other aspects of additive manufacturing. But it will also offer topics such as risk management, financial management of innovation, cybersecurity or intellectual property protection. What is important from our point of view is not only theoretical knowledge, but also practical skills acquired through real projects and workshops thanks to our own technological background,” Tomáš Jetmar, Head of the AM Systems Department, adds to the current global trend.

How these trends in the additive industry are to be perceived

We are entering a period in which additive technologies are improving current production processes and at the same time bringing completely new possibilities. For manufacturing companies that want to remain competitive, it is important to see these trends as an opportunity to transform and push the boundaries of innovation.

However, despite the unstoppable development of technology and artificial intelligence, it must be stressed that human expertise remains irreplaceable. It will thus need to have all the more attention paid to.

Therefore, ethical, human and social issues will come to the forefront, and with them efforts to regulate or protect society from the unintended consequences of its own technological progress. How society will manage to do this is difficult to predict at present.

Autor článku:

Michaela Winklerová

PR & Marketing Manager