Topological optimization

Using advanced algorithms and simulation techniques, the structure and shape of products are optimized. The goal is to minimize the amount and weight of material while maintaining the required strength and functionality of the product.

Optimization of mass and structures

The method brings a number of savings:

- Reduction of weight and material costs: Identifying surplus material and redundant structures in products reduces product weight while reducing material and manufacturing costs. Less material also contributes to sustainability and environmental friendliness.

- Increased strength and durability: The designed structures are as strong and durable as possible while minimizing weight. The optimization allows for an even distribution of stresses and loads on the product, increasing its reliability and durability.

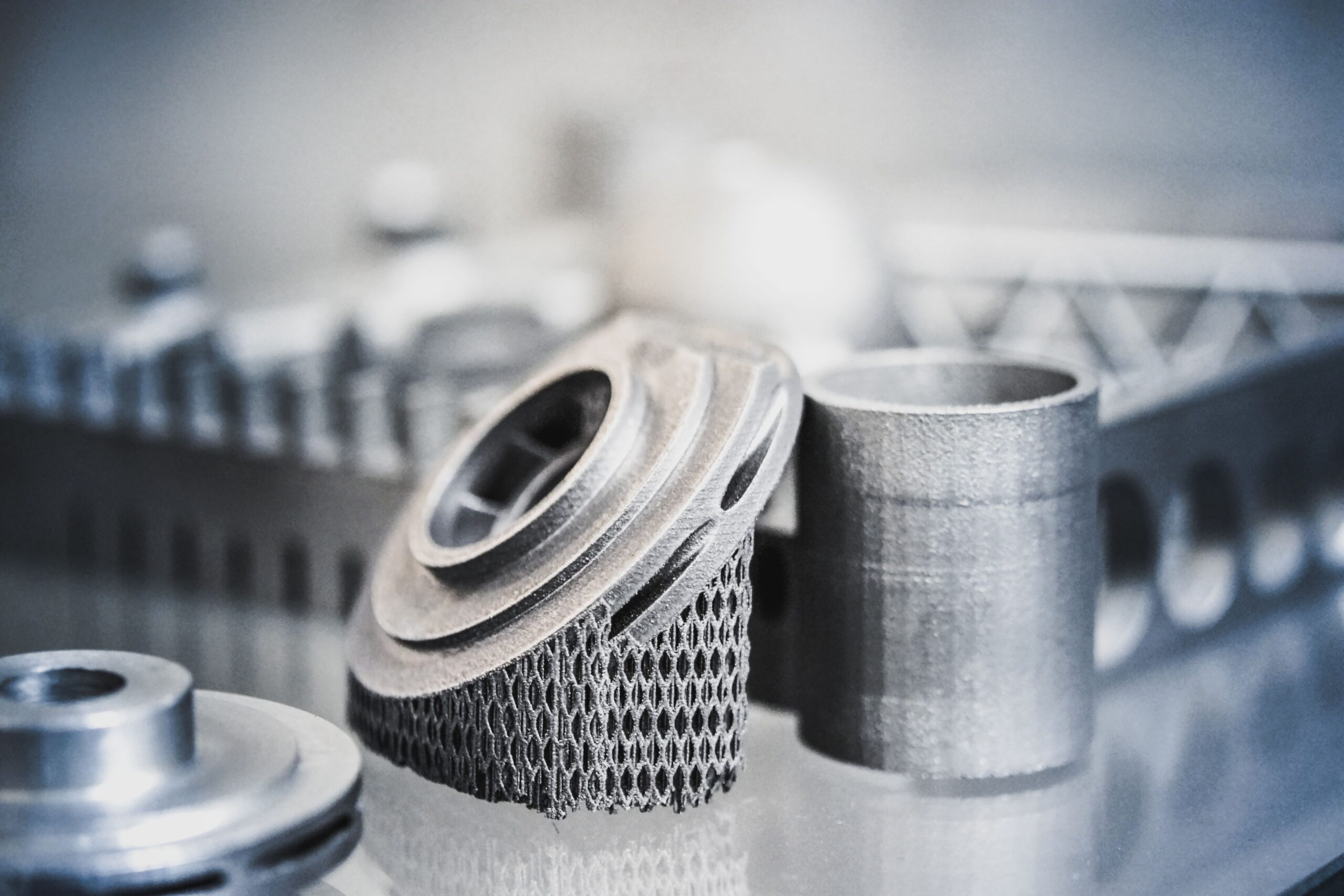

- Innovation and comprehensive design: The method allows experimentation with new and innovative designs. The algorithms are capable of generating complex structures and shapes that would otherwise be difficult or impossible to develop using traditional design methods.

- Rapid development and reduced time to market: Quickly iterating and testing different design variations allows to reduce product development time and accelerate time to market. This gives the company a competitive advantage and allows it to respond to market needs faster than its competitors.

- Integration with additive technologies:

Topological optimization is often used in combination with additive technologies (3D printing). Optimized structures can be easily fabricated using additive technologies, allowing the creation of complex and lightweight geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

Expert guarantee

Cardam has its own unique solution, thanks to which it is the only company on the market that can adapt the computing environment to the requirements of the problem being solved, rather than modifying the problem according to the capabilities of the application. The result is absolutely accurate output with the possibility of controlling it, or real application.