Digital audit, strategy and plan for Prestar, s.r.o., a manufacturing company

Prestar, s.r.o., a company that manufactures industrial automation machines, wanted to make its production and company processes more digital. However, it was encountering the usual barriers for small and medium-sized companies in implementing technological innovation:

- poor orientation in the solutions offered,

- expensive or inappropriate software for specific needs,

- inappropriate definition of the company’s needs,

- lack of a digitisation plan.

Thanks to the experience of Cardam, s.r.o. from Brain4Industry, which has extensive experience in implementing digitalization in many industries, Prestar gained:

- a complete digital audit of its operations,

- a digital strategy, including timetable and financial requirements,

- advice on the selection of a suitable system.

Prestar follows the trends in digitisation, tries to grasp this topic and develop its own digital skills. At the same time, the company is restructuring:

- development of planning – evaluation of the capabilities of the current ERP, development of the use of the APS system (advanced planning);

- improving the capabilities of equipment development (custom manufacturing, where each of their products is unique in its own way) – implementing PDM and then developing to PLM;

- ability of data-driven decision making in the company at various levels, i.e. having the ability to collect data on production, warehouses, and other processes in the company and being able to read in this data;

- development of the ability to get digitisation into their products – remote service, data tracking in delivered devices, etc.

Prestar is committed to digitisation and demonstrates this by supporting its employees in training in this area and Industry 4.0. They want to address digitisation comprehensively and, as can be seen, it affects multiple management levels and areas of the company. Virtually all employees and processes in the company will be affected. Their goal is to set a roadmap for the development of digitisation in the company in both a logical and a time sequence.

HOW THE COLLABORATION WORKED

Together with Prestar representatives we defined a clear task:

- Design a digitisation strategy within 7 years.

- Establish a timeline, logical continuity, financial requirements and return-on-investment.

At joint workshops we discussed all the key processes from the acceptance of the order, through its processing to delivery to the customer. A comprehensive analysis was conducted at the level of software tools used, hardware used, process design, management and organizational mechanisms and staffing.

It resulted in a joint identification of the main areas of potential development:

- development in the areas of planning (from business case acquisition, equipment development, production and commissioning at the customer),

- development in data collection,

- PDM/PLM development including the elimination of paper documentation,

- service and service support development towards Prestar products.

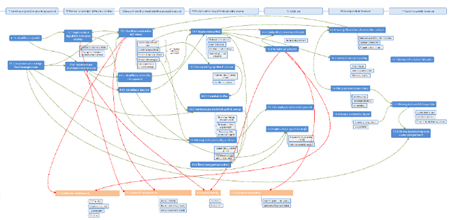

On the basis of the analysis and the identified potentials, a mind map of activities was created. The activities are divided into logical units and the continuity between them is visible. This map contains key development activities, but also complementary activities that will help to develop the company’s own know-how.

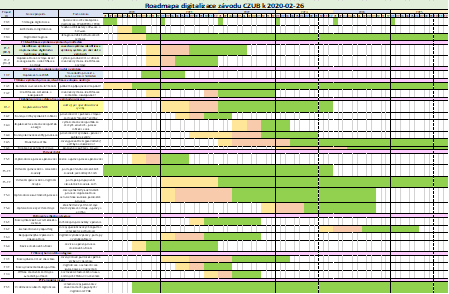

The last step is the creation of a Roadmap, or timetable, which contains the individual activities, the timetable, cost estimates (optimistic and pessimistic) and savings potential. It includes a projection of the costs over time versus the savings considered, showing the point at which the return on investment will be achieved. A brief description of each activity is included so that the activities can be revisited and elaborated on over time.

What Prestar gained by working with the Brain4Industry consortium

- Prestar was provided with a roadmap for the development of digitisation, the potential benefits were identified and the company was able to embark on the development of digitisation, reserving investment funds and tracking the actual delivery of benefits and costs over time.

- A replacement for the existing ERP system was identified as the first step since the system was inflexible, slow and could not be developed effectively.

Watch the case study video: LINK

What companies can gain from such cooperation:

- Impetus for the development of society in the field of digitalisation.

- An experienced and independent partner to help you navigate the issues.

The case study was prepared by: